Farm Life Journal - October 2019

October 22, 2019

By Tom Oswald

Bean Week and Apples with Caramels

The clock shows it is 4:15 a.m. as I write this month’s Farm Life Journal. I promised to send this off to Kelly Visser today as she does the editorial tweaks and formatting for the content you read online. She asked me for this edition last week, so I can imagine how much stress I put her through with my delays and procrastination. How could she know my writing style when she asked me to author this blog series?

Please note, by clicking links, you’ll be leaving a partially funded checkoff site.

The reality is that writing is one of the hardest things I do… and terribly hard to do on someone else’s timeline. My mind doesn’t work that way. In the Myers-Briggs personality type, I’m an INTP. My final version of a monthly post often altered up to the point I push the “send” button. For this month’s delay in posting, I have an excuse... it is “bean week,” so I’ve been really busy.

One of the benefits of serving on agricultural boards is the leadership training and people skills that go with it. I never thought of myself as a people-interested person, so the real awakening of these leadership positions has been understanding service and working with others. In more simple terms, I wish I knew as a young adult what I’ve come to see now in myself and others. I’ve come to really appreciate the differences in people and how they are wired. It helps me better understand my own strengths and weaknesses.

The perception that farmers work alone is partially true. But really, we don’t work in a void. Depending on the farm business structure, the dynamics of the farming team – be that with family or non-family – farmers are more people-connected than ever before. As part of the food supply chain for humans, we are in the ultimate people business.

So, what I find interesting is that the reason I enjoy agriculture so much is that it’s a wonderful place for a curious mind… that’s me. Yet, as someone who isn’t wired for the timeline of others (like a blog deadline), why would I choose to work under the timeline determined by Mother Nature? I’m not totally sure, but I have my theories. :)

So, what I find interesting is that the reason I enjoy agriculture so much is that it’s a wonderful place for a curious mind… that’s me. Yet, as someone who isn’t wired for the timeline of others (like a blog deadline), why would I choose to work under the timeline determined by Mother Nature? I’m not totally sure, but I have my theories. :)

Anyone who observes farming or agriculture knows that the weather drives so many issues and decisions. There’s a whole lot we can’t change, so understanding that change is a given is a great starting point. There are times I wonder if The Serenity Prayer wasn’t written with farmers in mind. Knowing the difference between the things we can change and those we can’t is important.

Harvesting Soybeans

When it comes to soybean harvest, there are a lot of fundamentals that must be taken into consideration. The soybean plant is processed whole through the combine. The plants are mowed off by a cutter bar, fed into the combine where the pods are threshed open and the round soybeans separated from the MOG (material other than grain). The combine travels 3 to 6 feet per second through the field, spreading the soil-protecting MOG residue behind it as evenly as possible. The lowest soybean pods hang from the plant starting about 2 to 4 inches above the soil surface, then at nodes every few inches to the top of the plant, depending on factors like genetics and stressors during the growing season. Cutting below the lowest pods is important to keep harvest loss as low as possible.

Once the soybeans are mature, you can start harvest. But it isn’t that easy. The cutter bar slides along the soil surface, so the ground can’t be too wet. If the stems are too ropey or green, they won’t process well which risks threshing or separating losses. The soybeans themselves need to be at an acceptable moisture for the on-farm storage or elevator delivery. Weather conditions are a big factor with soybean harvest, much more than with corn. Soybean moisture can vary greatly with precipitation or humidity as they are highly hygroscopic – meaning they tend to absorb moisture from the air.

My family has raised soybeans as a grain crop since the 1940s. Some farmers grew them earlier for forage, but I haven’t heard stories about that on our farm. There is a photo of a couple of brothers from the neighborhood custom harvesting soybeans for my family shortly after WWII. I think my dad and grandpa bought their first combine around 1948. With decades of experience, my dad and a few other farmers I know talk about an annual “bean week.”

My dad would say, “Every year there’s a week to combine beans. When that week arrives and the beans are ready, you focus on combining beans. If you miss that week and don’t get done, you will mess around the rest of fall trying to get done.”

I know some farmers who base their equipment sizing or availability on the number of acres they need to cover to complete soybean harvest in seven days. The problem is you don’t know when bean week will arrive!

In 2009, one of the most stressful harvests I can remember, bean week didn’t happen until after Halloween. It happened, but the waiting and trying to get a few pieces done in the meantime was a killer for patience.

When Susanne and I were first married, we lived in the town of Cherokee. The second Halloween in that home we greeted trick-or-treaters who came to the door wearing snowmobile suits or other winter wear. A blizzard hit and many elements of harvest came to a standstill. Fortunately, we were done with harvest, but you never forget what’s possible as you accumulate years of harvest experiences. Snow on soybeans can be a disaster.

Around here, bean week might be any seven day stretch from late September through October depending on the number of factors noted above. Big combines, harvest support and trucking can really eat acres in a hurry once the weather and crop condition window opens. My combine was the smallest one offered by Case International when I bought it new in 2012. It cuts 30 feet wide or twice the swath of the one we used when I was in college in 1978. But it is only two-thirds the width of the 45-foot wide headers that some farmers use for soybeans in Iowa.

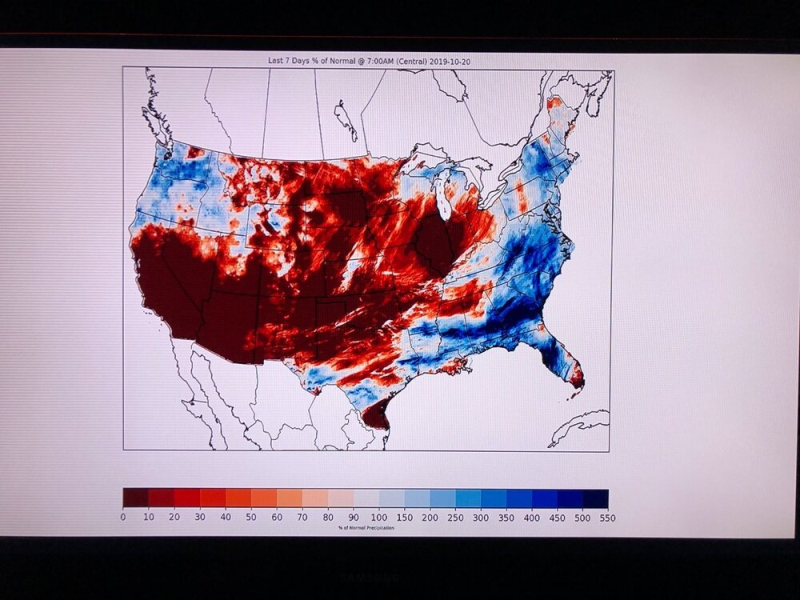

The week ending Sunday, October 20 was “bean week” around here and many other places where the soybeans were fit to harvest.

Since last week it’s been wet and cold, which is not beaning weather, so I’m glad to be done with all but a very small patch. Bean week 2019 wasn’t a perfect week because it was too cool and humid, which limited the amount of time the soybean stems were fit to process or the seeds too wet for market, but we had a pretty good run.

Since last week it’s been wet and cold, which is not beaning weather, so I’m glad to be done with all but a very small patch. Bean week 2019 wasn’t a perfect week because it was too cool and humid, which limited the amount of time the soybean stems were fit to process or the seeds too wet for market, but we had a pretty good run.

Over the more than two decades I’ve operated a combine, there are days when you might only run from 3 p.m. until sundown as there is too much humidity and lack of sun. The moisture sets in and things grind to a halt. Then there are other days when you can begin mid-morning and don’t quit until past midnight when the wagons or trucks are full. At least auto-steering systems help keep the combine going straight! Once, years ago, I forgot I hadn’t correctly set the clock on the combine radio and only realized it was after 2 a.m. when I shut down and saw the correct time on my pickup truck clock driving home. I had been creating dust and noise across the road from a local town and I still wonder if they were thinking, “Is he ever going to quit?” At least the loads were full.

As for this year, I noted in last month’s blog that I didn’t know how the yields would end up. It’s hard to estimate soybean yield. The pods per plant can vary, the seeds per pod can vary, seed size can vary which impacts how many seeds fill a bushel. White mold did take a toll on my crop, but not as bad as I feared. The difference between varieties was substantial. I can say the crop would have been above average without the disease and came in below average by 5 to 10%. For future years I have an aggressive white mold management strategy planned.

Recently, on Twitter, people were sharing their harvest lunch foods and treats. We used to say that planting and harvest ran on sugar and caffeine, but we’ve evolved a bit since then. When my mom was alive, sometimes I’d eat lunch with her, and it was always good. She’d have plenty of cookies, apple pie or other things to keep us going. Susanne is great in the kitchen, but when she isn’t running the grain cart chasing the combine, she is at work in town.

Some of the things in my small cooler that goes to the field are apples and caramels. Note, I didn’t say caramel apples. Even with auto-steering, eating while operating equipment requires easy-to-eat foods. If things are too sticky or crumbly, you make a mess of the tractor or combine cab. You need to be able to feed yourself with one hand while operating controls with the other.

I love Jonathan apples in the fall. We either get them at the local orchard or Deal’s Orchard in Jefferson. There’s still a challenge unwrapping the caramel wrappers, but our method is to bite the apple, pop a caramel and combine them in your mouth. When you’re done with the apple, the key is to open the cab door just enough to toss the core without letting too much dust in or bouncing the sticky core off the cab window.

Next month we’ll talk about corn harvest.

Stay safe out there.

Tom